iRoss – Fluxmanager™ Single Phase 튜브 & 파이프 열처리 시스템

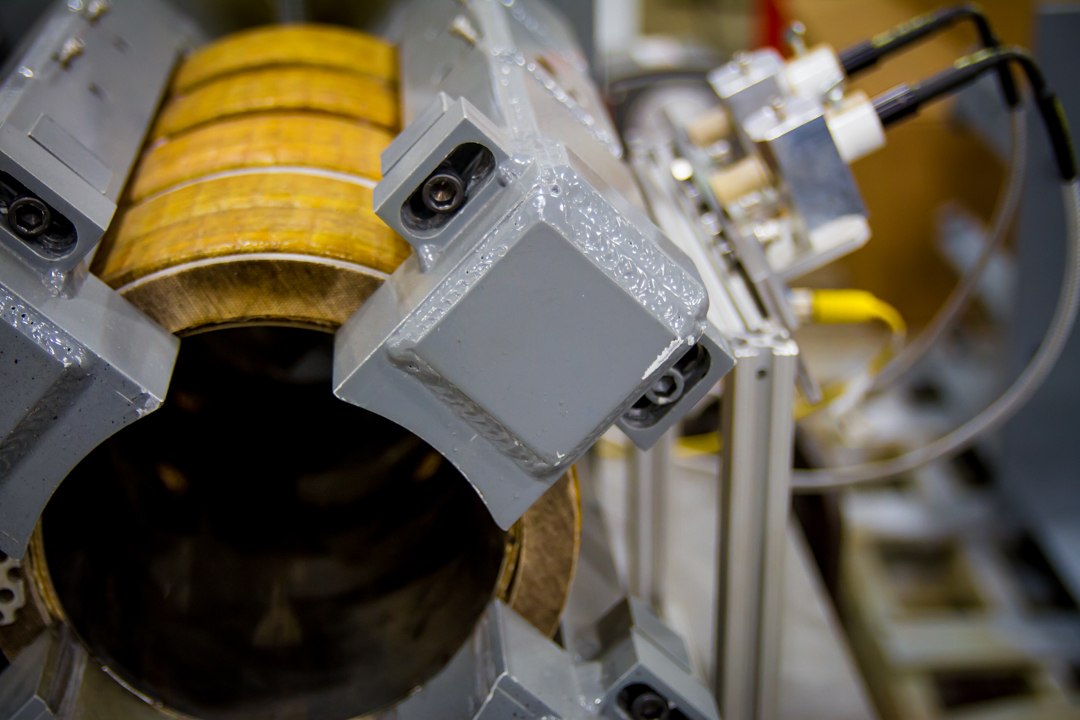

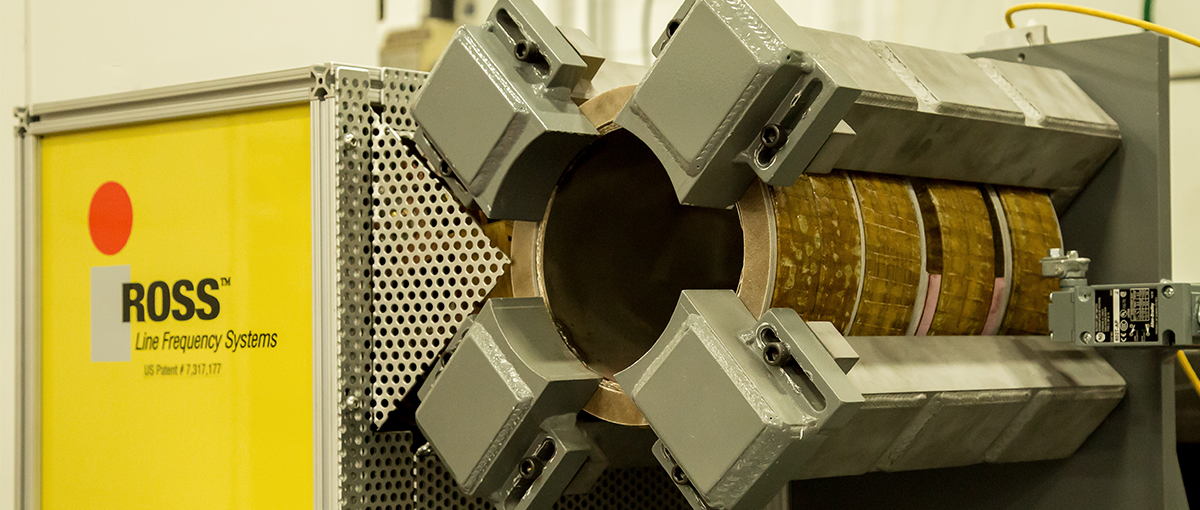

IROSS™ Fluxmanager™ Pipe-End Heating Units are designed for heating a variety of tubular products. These systems utilize patented Fluxmanager™ induction heat treatment technology that yields superior temperature uniformity compared to conventional medium frequency designs.

Features

Applications:

- Stress relieving

- Preheat for welding

- Annealing

- Normalizing

- Removal and curing of coatings

- Friction welding and swage preheating

Fluxmanager™ Features/Benefits:

- Deep and uniform temperature distribution, ID/OD, circumferentially and longitudinally.

- Flexibility: 6 coil diameters cover all OCTG pipe sizes

- Modular: Robust and unitized system

- Infrared monitoring options

- Data logging capability for traceability

- Shaped flux concentrator for increased efficiency

- Deionized water NOT required

- Versatile: 50 or 60Hz / 350 – 600VAC input

- Minimal amount of water needed – only 8 GPM required for cooling

Tech Specs

| Dimensions (W x D x H) | Coil (Max) : 45.5” (725 mm) x 36” (915 mm) x 30.25” (760 mm) |

| Standard Power Rating | 167 & 192 kVA, 50/60 Hz, Single Phase |

| Standard Coil Assembly For Pipe O.D. Sizes: (Other sizes available upon request) | # 562 2.375” – 5.625” (61 – 143 mm) |

| # 762 4.000” – 7.625” (102 – 193 mm) | |

| # 1062 7.625” – 10.625” (193 – 269 mm) | |

| # 1462 10.625” – 14.625” (269 – 371 mm) | |

| # 1762 14.625” – 17.625” (371 – 448 mm) | |

| # 2062 17.625” – 20.625” (448 – 524 mm | |

| International voltages are standard |

Accessories

- Hydraulic lift table

- Infrared temperature control

- Data archival recipe management

- Pneumatic coil shuttle options

- Optional stand alone water/chiller system – no deionized water required