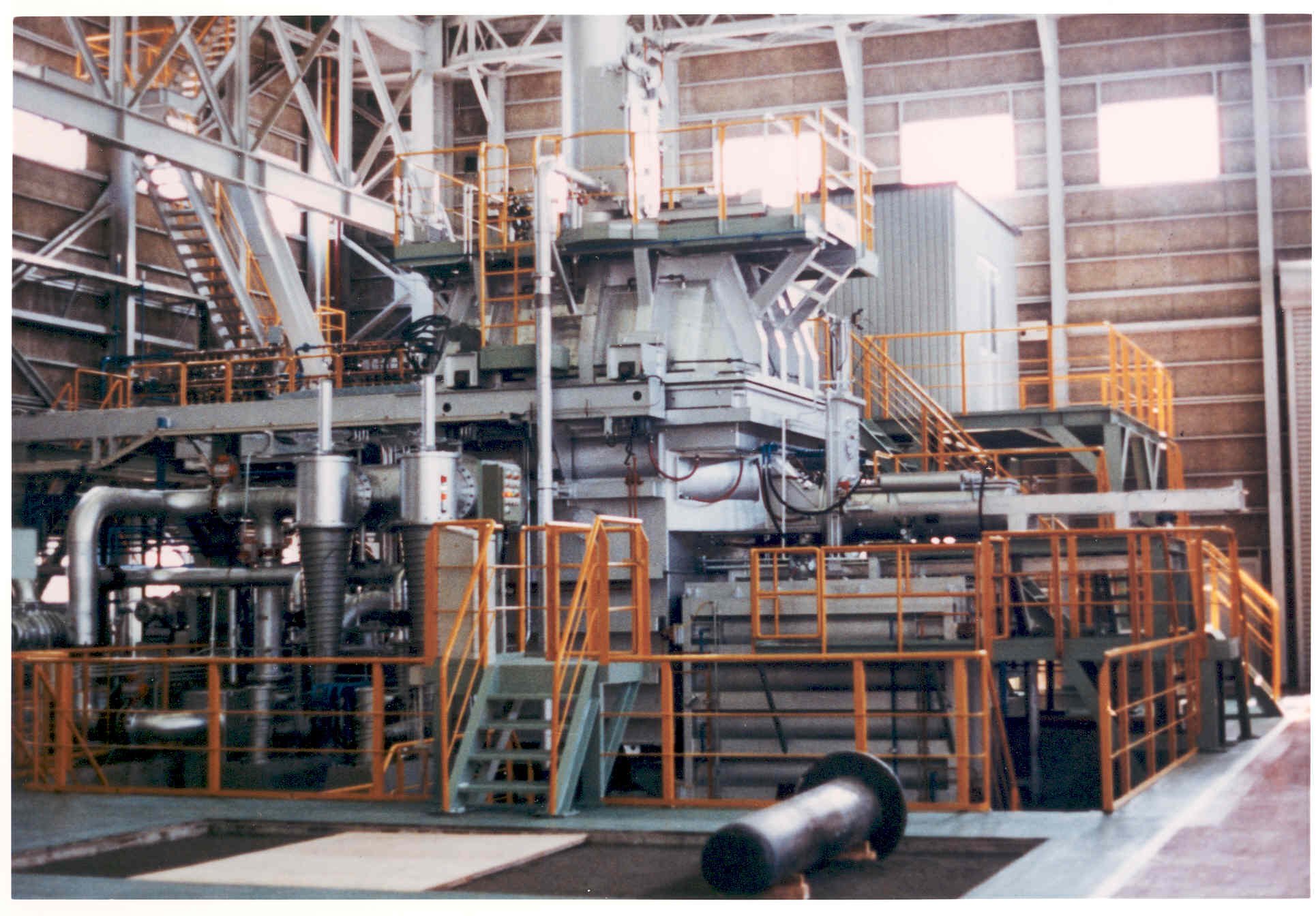

Electrode VIM Furnaces

Electrode VIM systems은 가장 큰 진공유도용해로 시스템으로 5Ton 부터 30톤에 이르기 까지의 제작 범위가 가능함

특징

• 견고한 스틸쉘 인덕션 로체

• 최적의 진공시스템 설계로 고효율의 안정적인 진공 유지

• 신속한 로체 교체로 비가동 시간 최소화

• 고효율의 Inductotherm 전원장치 적용

• Mold, Melt, Charging, Tundish 등 다중 챔버 구성 가능

• 몰드카, 턴테이블 및 상부주입, 하부 주입등을 통한 다양한 주입방법 적용 가능

• 고객 요청에 따른 맞춤 설계 제작 및 Control 시스템 구성 가능

기술사양

Multiple Charging Systems:

• Large capacity overmelt chargers for primary bucket charging of high density charge materials. Charge weights to 5t are possible depending on the furnace refractory dimensions. Large capacity chargers incorporate dual hoists to allow controlled opening of charge buckets.

• Secondary overmelt devices for temperature probe insertion, sample taking, and late alloy additions

• Overmelt chargers utilize a custom-designed water-cooled overmelt isolation valve to over 1.3 m in diameter incorporating vacuum seal protection when open for increased reliability

• Vibratory side feeders for primary charging of low density charge materials

• Other charging systems for low headroom installations are available

Vacuum System:

• Three stage vacuum pumping system incorporating oil sealed rotary pumps or dry type screw pumps, roots type mechanical blowers, and oil vapor booster pumps for finalizing vacuum levels in the 10-3 Torr range

• Oil wetted vacuum filters for control of pyrophoric additions such as NiMg

• Large electrode VIM systems may incorporate steam ejector or steam hybrid vacuum pumping systems

• State-of-the-art safety systems incorporating overpressure relief valves and argon purging

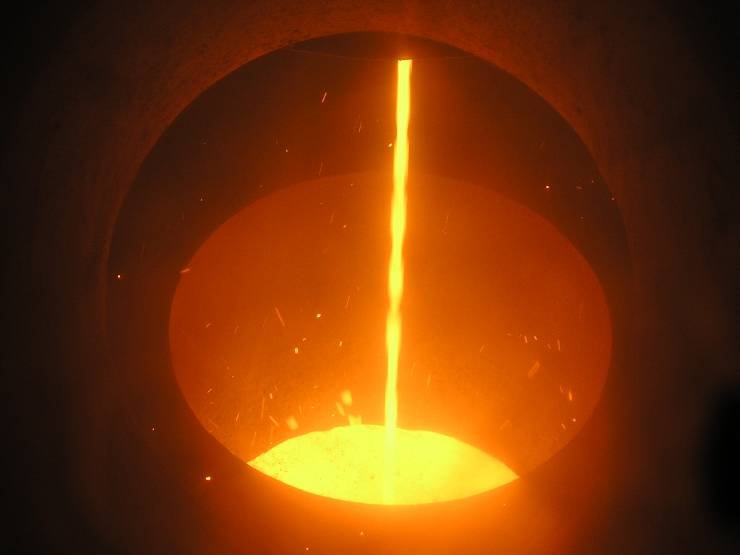

Mold Pouring:

• Hot tundish insertion chargers configured to insert an externally preheated refractory tundish into the pour position within a few minutes

• Deep tundishes on large furnaces can contain stopper rod assemblies

• Programmable control of mold car / turntable movement

Controls:

• Computerized control and SCADA systems

• TV cameras on remotely actuated site ports for remote operation

Accessories

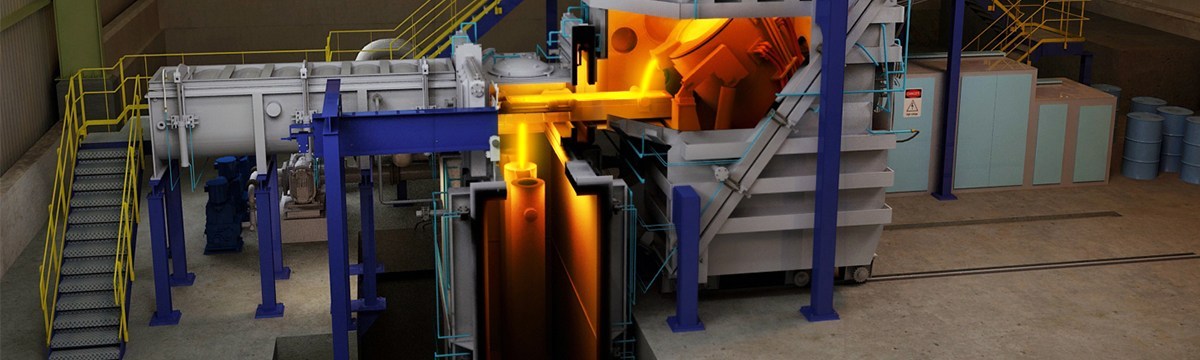

Two furnace layouts are typically utilized: Rollaway Head and Door Mounted Furnace.

Rollaway Head furnaces have the following features:

• Good access to the furnace top and spout

• Simple power supply bus arrangement

• Good ability to inspect the lining and furnace coil

• Able to frit lining or perform wash heat in open air

Door Mounted Furnaces have the following features:

• Very easy access to melt chamber for cleaning

• More complicated power supply bus required

• Easy access to all of coil

• Less platforming required since there is no head movement