Applications

For most metals, melting is the first step in producing a useful product. Inductotherm is the leading manufacturer of induction melting systems and is the most recognized name in foundries today. We provide a variety of furnace types and capacities — from coffee-cup-size units for melting precious metals to furnaces holding hundreds of tons of iron. From state-of-the-art charging to high-production automated pouring equipment, Inductotherm technology means fast melt rates, maximum efficiency, low metal loss and precise temperature control for optimum metal quality. We are involved in many applications and bring our advanced technology to your entire melting, heating, holding, pouring or coating operation.

Alloy Manufacturing

Ingot producers depend on Inductotherm systems for multiple alloy flexibility and product uniformity. For ingot makers, the correct amount of induction stirring is a key factor in producing ingots that are metallurgically homogeneous from start to finish of each batch. Our induction melting systems are designed to produce the best level of stirring for each customer’s application.

Aluminum Melting

Converting alumina into pure aluminum and ultimately into useful aluminum alloys is an energy-intensive process. That’s why energy-efficient furnaces manufactured by Inductotherm have proven their value in aluminum plants worldwide. We offer a range of furnace technologies to ensure we deliver you the most technologically advanced system for aluminum.

Copper & Copper Alloy Melting

From removable crucible furnaces, used to melt just a few pounds of brass for custom castings, to casting giant bronze ship propellers, we build furnaces and complete melt shop systems for virtually every copper and copper alloy application. Inductotherm’s advanced induction technology has given copper and copper-based alloy producers and casters the ability to melt with precise metallurgical and temperature control, low metal loss, minimal gas pickup and an environmentally clean process.

High Temperature Graphite Heating

Inductotherm builds most of the world’s zoned induction heating coils and multiple output power supplies used in the manufacturing of ultra-high-temperature advanced materials such as carbon carbon. We know that when it comes to graphite heating, maintaining the desired temperature profile within the susceptor is absolutely critical in order to achieve maximum productivity. That’s why our systems allow manufacturers to fully control the temperatures at all levels of the hot zones in which the processing takes place.

Induction Heating for the Steel Industry

Providing the rolling mill with a continuous supply of uniformly heated steel slabs, billets, bars and blooms at the proper temperature is crucial to efficient mill operations. Our induction heating systems for bars, blooms, billets, plate, strip and slabs are used prior to rolling operations. Temperature control and consistency are maintained from the surface to the core and over the length of the product. For coating steel strip, Inductotherm brings the world’s most advanced induction technology to the coating line.

Investment Casting

Induction melting is widely used in investment casting applications. We offer a wide variety of air and vacuum induction melting furnaces that are ideal for the investment casting of virtually all metals. Specialty furnaces, like our rollover furnace, are specifically offered to this market for nonferrous and ferrous alloy castings ranging from jewelry to precision castings for turbo chargers.

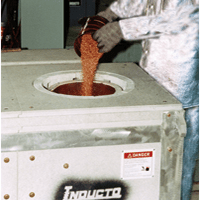

Iron Melting

Iron is the most used of all the metals, comprising 95% of all the metal tonnage produced worldwide. Its combination of low cost and high strength makes it indispensable in almost every industry and that is why we make sure that our induction melting equipment is the most efficient on the market when it comes to melting it! We offer equipment designed for virtually every iron melting, heating, holding and pouring operation.

Precious Metals Melting

Inductotherm manufactures clean and efficient melting systems used in processing precious and platinum group metals for refining, scrap melting, jewelry manufacturing and other applications. We recognize that even minute metal loses and metallurgical impurities are extremely costly which is why we ensure our technologies increase metal recovery and lower processing costs in each step of the cycle. With the range of precious metals applications spanning not only the jewelry industry, but medical, chemical and automotive industries as well, the efficiency and cost effectiveness of induction melting with Inductotherm equipment has become vital to the production of these metals.

Rare Earth & Other Materials Melting

Inductotherm’s commitment to serving the metals and materials industry does not stop at iron, aluminum and copper. In addition to steel, zinc, and precious metals, Inductotherm equipment is used to manufacture reactive metals, rare earths, titanium, silicon, lead, magnesium, uranium, depleted uranium, and calcium, among others.

Recycling & Processing

Induction melting is ideal for recycling UBC (used beverage cans) and other lightweight aluminum scrap because it is a flame-free process (minimal oxidation) and provides the stirring needed for uniform alloys. Our induction chip melters keep scrap costs low by offering high recovery rates to all types of foundries. Chips and other manufacturing by-products (shavings, punchings, etc.) are ideal charge and provide a low-cost and high-quality source of charge materials.

Silicon Melting

Inductotherm equipment can be used to melt silicon for a variety of applications such as creating most semiconductors which are important in electronic technology and to help reduce the cost of solar-grade silicon. Our equipment delivers heat directly or indirectly into a mass of liquid silicon with controlled stirring, allowing faster silicon production on a much larger scale, making induction furnaces a preferred choice for the next generation of thermal equipment for solar-grade silicon production.

Steel & Stainless Steel Melting

Inductotherm plays a key role in the steel industry’s productivity revolution by building technologically advanced production systems for steelmakers and steel product manufacturers worldwide. Inductotherm builds induction melting systems used in several steelmaking applications. These include melting steel scrap to produce a variety of steels and steel castings. Inductotherm offers equipment to make stainless steel, alloy steels and master alloys for the casting industry and various applications including billet, shot, powder and other specialty applications.

Universities & Laboratories

We understand that in order to develop big ideas, you have to start small. That’s why we have a wide variety of equipment that is ideally suited for these applications. The future of the metallurgical and foundry industries is being researched and developed in many schools and research facilities across the globe. To facilitate this research many of these institutions utilize Inductotherm equipment in both air and vacuum environments.

Vacuum & Controlled Atmosphere Melting

Vacuum and controlled atmosphere melting systems are used for the world’s most demanding casting applications. The creation and casting of super alloys and many other advanced and reactive metals requires sophisticated vacuum or controlled atmosphere melting and remelting systems. Many high quality specialty metals and materials are produced and refined using Inductotherm melting systems.

Zinc Melting

Inductotherm designs and manufactures the most advanced zinc and zinc alloy melting and holding systems to suit your needs. Our induction furnaces and power supplies are used in strip galvanizing, wire galvanizing, hot-dip galvanizing, cathode melting, ingot melting, alloying, holding and emergency holding. With different types of furnaces and power supplies, we build a system to suit your application and budget.