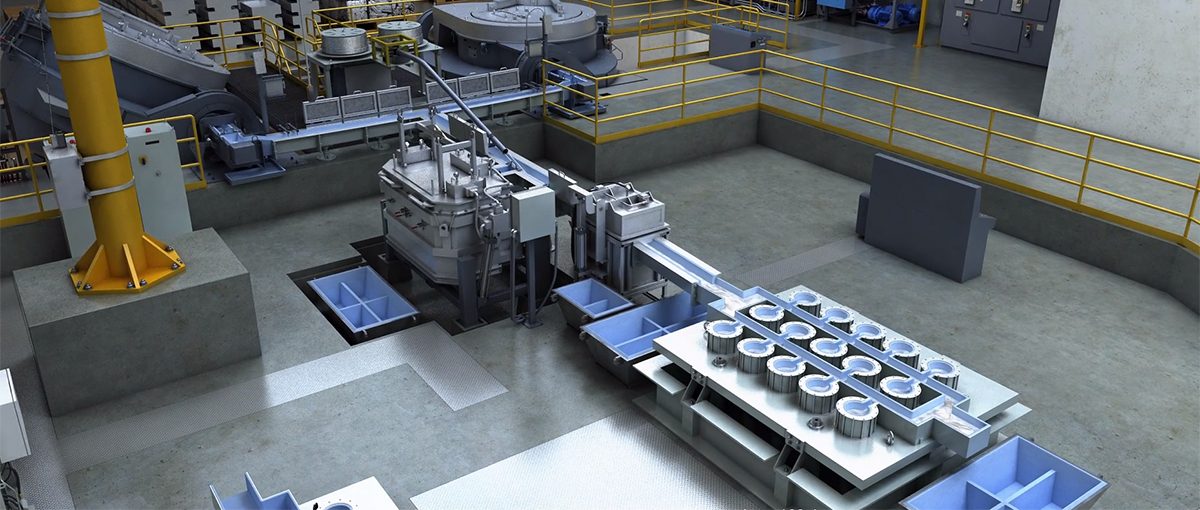

Hybrid™ Furnaces

The Perfect Relationship – the Coreless Inductor united with the Channel Uppercase – Ideal for Large Aluminum Casting Operations and Other Metal Industries

Inductotherm’s Hybrid™ Furnace draws on the design advantages of both the coreless and channel melting holding furnaces. The coreless furnace provides maximum alloy flexibility with significantly lower capital and installation costs while the channel furnace can hold large quantities of metal at low holding power levels for extended periods of time for economical high-volume production. The Hybrid™ Furnace enables operational flexibility, allows for inert gas cover and offers quick alloy changes making this furnace attractive for a variety of large aluminum casting applications that require tight specifications and tolerance for the aluminum components. This enables our customers to produce high-quality aluminum billet and commercial slabs in a variety of alloys.

Benefits

The “Powerhouse” Coreless Inductor and the “Rugged” Channel Upper Case

The coreless inductor with super heating capability is the heat source for the melting and holding operations. The furnace is operated using a solid-state power supply with a Melt-Manager Plus® control system to control the melt process. The power supply is designed to meet the most optimal frequency for the application.The use of a coreless inductor allows the Hybrid™ Furnace to be fully emptied after the melting and casting operation has taken place, as opposed to a channel inductor alone, which requires a metal heel be maintained at all times with a constant energy supply to keep the metal molten. This allows for alloy flexibility, since a new material mix can be input after the furnace has been emptied.

The coreless inductor is mounted onto the bottom of the channel upper case of the Hybrid™ Furnace.This ensures high strength, integrity, and refractory life. It incorporates a lift and swing lid that provides access to the furnace hearth for charging material such as sows and ingots in a variety of sizes. The case’s thick refractory lining assures minimum temperature loss and allows for thermocouples to be embedded for continuous temperature measurement. Combined with a temperature control system, the thermocouples provide precise control during the entire holding and pouring process to keep the aluminum in the desired temperature range.

Additional Benefits to Hybrid™ furnaces:

- The coreless inductor allows for alloy flexibility.

- The use of a coreless inductor allows the power supply to be designed for the most optimal frequency for the application.

- Typically built with a lift and swing lid, this furnace provides access to the furnace hearth for charging of various size materials, including sows and billets.

- A thick refractory lining in the uppercase assures minimum temperature loss and allows for embedded thermocouples for continuous temperature measurement.

- A dross door together with a back-tilting system allows for convenient dross removal from the melt surface.

Features

Size and Structural Support

The Hybrid™ Furnace is available in standard sizes (10-40 tonnes) and can also be adapted to larger applications. It is mounted in a rugged stanchion together with hydraulic cylinders for dependable tilting performance. Incorporated into the design are a set of load cells that indicate the weight of the metal, a variety of fume exhaust devices that ensure a clean work environment, and a dross door together with a back tilting system that allows for dross removal from the melt surface.

Various Charging and Pouring Configurations

Metal dispensing for the Hybrid™ Furnace is available in either a trunnion pour or a siphon arrangement, similar to channel furnaces. The siphon pour spout draws the metal from below the metal surface.

Controls

A PLC system controls all aspects of the tilting and pouring process, allowing for controlled metal flow from the furnace into the launder and then to the caster. There is a launder level control that uses laser feedback to control the furnace tilt angle and the resulting metal level in the launder. A temperature controller keeps the bath temperature in the desired range.