Meltminder 300 Melt Shop Control and Management Systems

Our Meltminder™ 300™ Melt Shop Control and Management System provides the highest level of melt automation technology to support precise, highly responsive and fully programmable control, which is important to the safe and efficient operation of today’s induction melting equipment.

Features

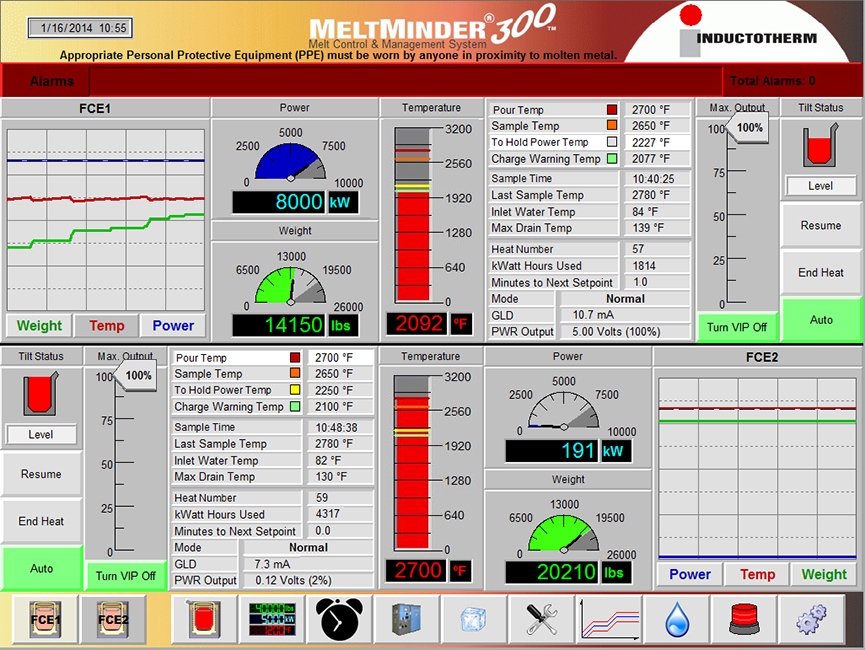

Meltminder™ 300™ Melt Shop Control and Management Systems are PLC-based and take the features of our Melt-Manager™ Plus™ Control Systems a step further. They are designed around an industrial ethernet network to provide the furnace operator with the tools needed to precisely control and monitor the entire melting process, from charging to melting to tapping. Meltminder™ 300™ Melt Shop Control and Management System includes all the features provided by Melt-Manager™ Plus™ Control System as well as the following benefits:

- Immediate Access to System Data: Provides melt shop supervisors and managers with the broad range of data they need to monitor, evaluate and plan melt shop operations. Customers have access to a comprehensive MySQL database as well as variables within the PLC, providing limitless access to operational data.

- Melting System Control: Temperature based controls can calculate up to designated temperatures and apply hold power to reduce energy usage and avoid superheating. This control system also provides automated sintering and coldstart features.

- Ease-of-Use: With its easy-to-use and intuitive screens and robust industrial hardware, this system is surprisingly easy to master and maintain. Its graphical presentation of operational data makes the information clearer and easier to understand.

Tech Specs

| Standard Features | Automated Control of the Complete Melt Cycle |

| Real-Time Modeling of Furnace Bath Temperature | |

| Automated and Fully Programmable Control of Furnace Sintering | |

| Cold Start Schedule Control | |

| Real-Time Monitoring of Furnace Charging with Load Cells | |

| Real-Time Monitoring of System Water Temperatures | |

| Interface with Power Utility Demand Controller Systems | |

| Comprehensive Record-Keeping and Detailed Data Generation | |

| Touch Screen Remote Display | |

| System Operation Diagnostics | |

| Interface With Plant Network | |

| Holding System Control | |

| Energy Consumption Monitoring | |

| Optional Features | Analysis of Available Materials and Recommendations for Charge Make-Up |

| Weight, Power and Temperature Scoreboard | |

| Factory Tested | Critical Components |